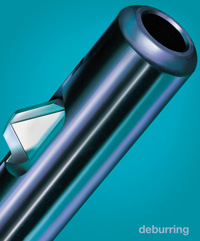

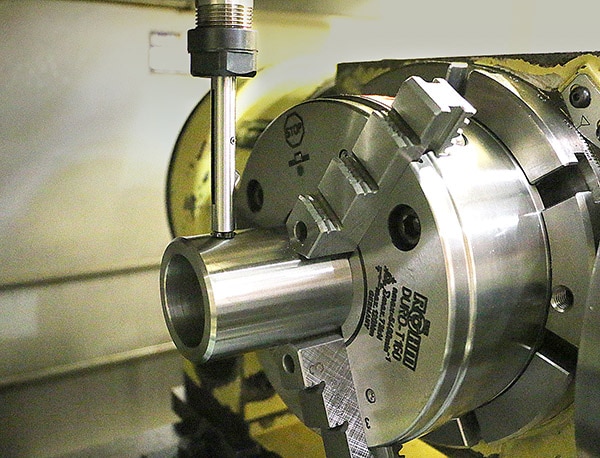

อุปกรณ์ลบคมรูเจาะบนชิ้นงาน

Deburring Tools for Holes – Deburr Both Sides In One Pass

COGSDILL Deburring Tools สำหรับลบคมชิ้นงาน โดยสามารถที่จะลบคมทั้งสองด้านได้ในเวลาเดียวกัน ทำให้สามารถลดเวลาในการผลิตลงได้มากและยังได้ชิ้นงานออกมามีคุณภาพสวยงาม อายุการใช้งานของใบมีดยาวนาน เหมาะสำหรับการผลิตงานที่เป็นแบบ Mass Production อาทิเช่น อุตสาหกรรมผลิตชิ้นส่วนรถยนต์ เป็นต้น โดยมีชนิดของ Deburring Tool ให้เลือกใช้งานดังต่อไปนี้

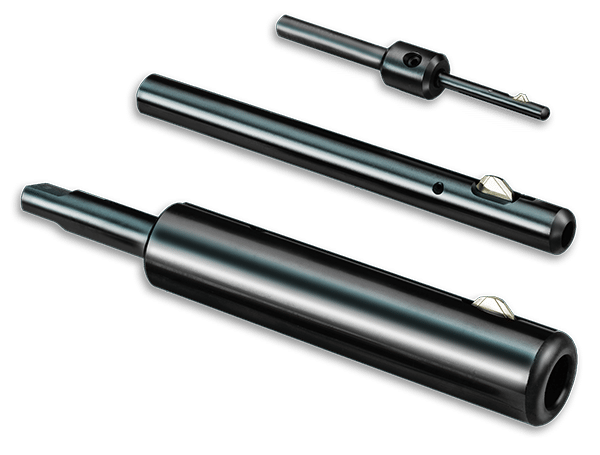

- Burraway Tool

- Burr-Off Tool

- Smooth Edge Deburring Tool

- Micro-Limit Tool

- Ellipti-Bur

- Nobur Tool

A one–pass solution to your hole–deburring problems!

Deburring holes is usually a costly and time-consuming operation. The back sides of holes are particularly difficult, as they are frequently inaccessible with conventional deburring tools.

Cogsdill Tool products offers you a better way to get rid of those troublesome burrs. BURRAWAY and BURR-OFF mechanical hole-deburring tools remove burrs on the front, back and both sides of drilled holes in one pass…fast, easy and economical solutions for your hole-deburring problems.

BURRAWAY TOOL

Burraway Tools are available in both inch and metric programs, The tool can remove feather edges or heavier burrs on both sides of the hole.

How it works…

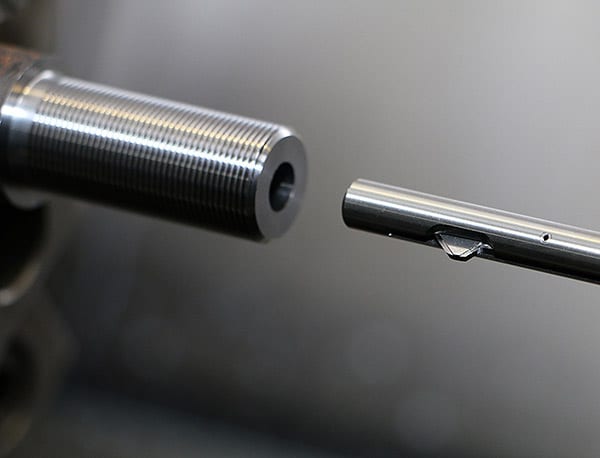

Upon entry, spring tension holds the replaceable and adjustable cutting blade in the extended position as it removes the burr on the front of the hole.

As the feed load increases, the pre-set spring tension is exceeded and the blade retracts automatically as the tool passes through the workpiece. (The crowned and polished top surface of the blade will not mar the inside surface of the hole.)

Spring tension again causes the blade to extend as it emerges from the ID of the part; the burr is removed on the back side of the hole on the return stroke.

BURR-OFF TOOL

Burraway Tools are available in both inch and metric programs, The tool can remove feather edges or heavier burrs on both sides of the hole.

How it works…

- Integral remove the burr from the front of the hole as the tool enters the hole.

- The slotted design allows the tool to “collapse” under load as the tool feeds through the workpiece. The crowned and polished top surface of the cutting edges will not mar the inside surface of the hole

- The back of the hole is deburred on the return stroke

เครื่องมือบดผิวในรูเจาะสำหรับงานที่ต้องการผิวรูเรียบพิเศษ

Burnishing Tools (Roller Brunishing Products)

Roller burnishing is a surface finishing technique in which hardened, highly polished steel rollers are brought into pressure contact with a softer piece part. As the pressure generated through the rollers exceeds the yield point of the piece-part material, the surface is plastically deformed by cold flowing of sub-surface material. The result is a mirror-like finish and a tough, work-hardened surface with load-carrying characteristics that are superior to finishes obtained by abrasive metal-removal methods.